-

Want to Call Us?

07450 447958

-

You can Email us at:

office@kraken-ndt.co.uk

-

Verify us at: BINDT

PCN number: 346036

- Like what you see?

We understand your needs for NDT inspections and compliance

About our NDT Inspections and Services

Delivering regulatory compliant Inspection Services

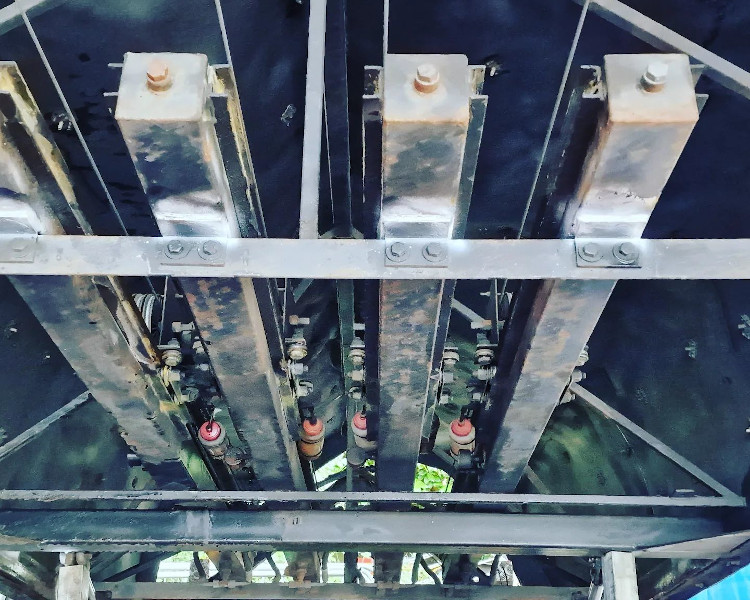

Kraken-NDT operates in accordance with National regulatory requirements regarding EN ISO/IEC 17020:2012 Conformity assessment - Requirements for the operation of various types of bodies performing inspection for Non-Destructive Testing services primarily within the UK Amusement device, Commercial Aviation and Commercial Facilities Management industries..

We've Repution for Excellence

We Build Partnerships

Guided by Commitment

A Team of Professionals

Our Values

Our values are using the correct systems and processes to ensure Compliance, Accuracy, Consistency and Efficiency.

0

Total Projects to be completed this year

0

Industry Specialisations

0

Hours of Work

0

PCN Certified methods of NDT Inspection

We Are non-destructive testing Specialists In

What We Do

Applied to all material ensuring the surface condition is suitable for examination and ensuring visible defects are not present.

Applied to coated surfaces, eddy current can effectively and efficiently detect surface breaking discontinuities without the need for coating removal and re-application.

This is widely used to detect surface breaking flaws. This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities.

Magnetic Particle Testing (MPI)

Applied to ferrous material. MPI can be carried out using colour contrast and fluorescent techniques using portable yokes.

Manual Ultrasonic Testing (UT)

Applied for the inspection of weldments, corrosion mapping, thickness examination and lamination inspections.

Kraken-NDT offers Non Destructive Testing Off-Site at our fully equipped test facility at our Headquarters in Essex. Our technicians carry out all activities and work within all the necessary health & safety requirements that are applied within the industry.