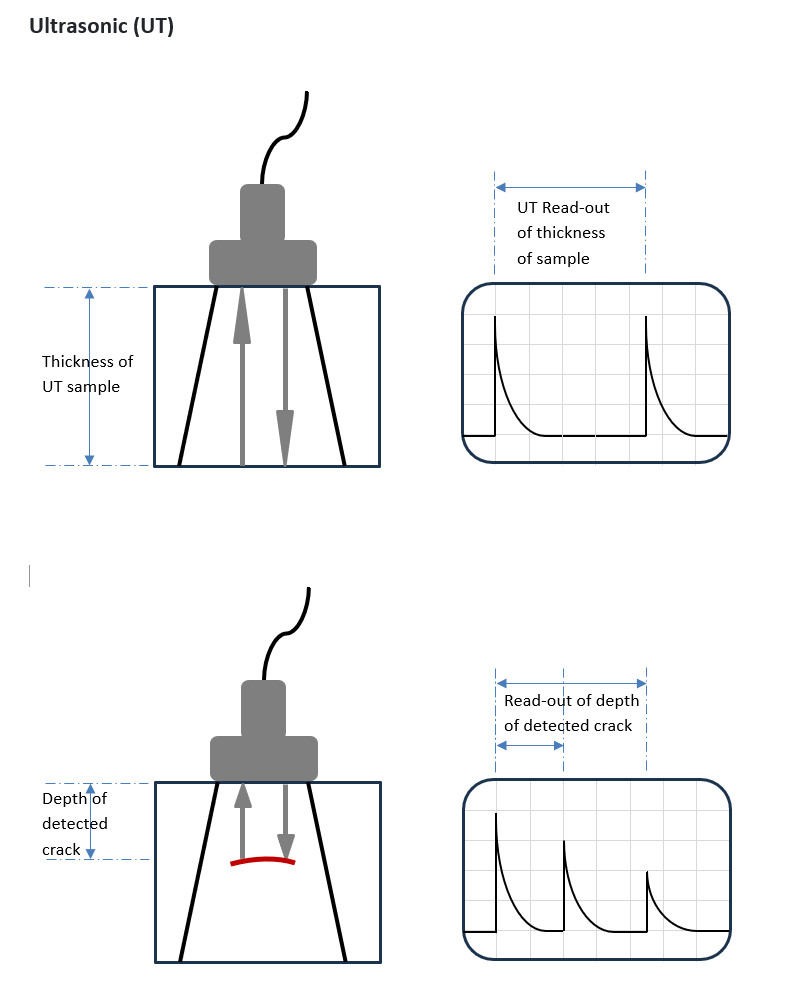

Ultrasonic (UT) NDT Inspection Methods

This technique sends ultrasonic waves to the desired object or part. Short pulse frequency waves from 0.1 to 15 MHz are sent to detect the flaws. It can measure the thickness of objects when assessing pipeline corrosion or related objects.

UT has two components for detecting flaws, namely, transducer and detector. Typically, a piezoelectric transducer is connected to a flaw detector, and this transducer is moved over the surface being examined. A coupling is used to transmit the ultrasonic waves and efficiently enhance accuracy.

There are two types of transmission: pulse-echo and through transmission. In the pulse-echo technique, the same transducer acts as an emitter of ultrasonic waves and receives the echo signals back for analysis. The transmission uses a transducer at one end and a receiver at the other.

Submit a review/ Get in touch