Dye Pen NDT Inspection Methods

It is also known as Liquid Penetrant Testing, in which a fluorescent or colour dye is applied to the surface under examination. Aerospace and medical industries usually use this technique to visualise the defects in machinery components.

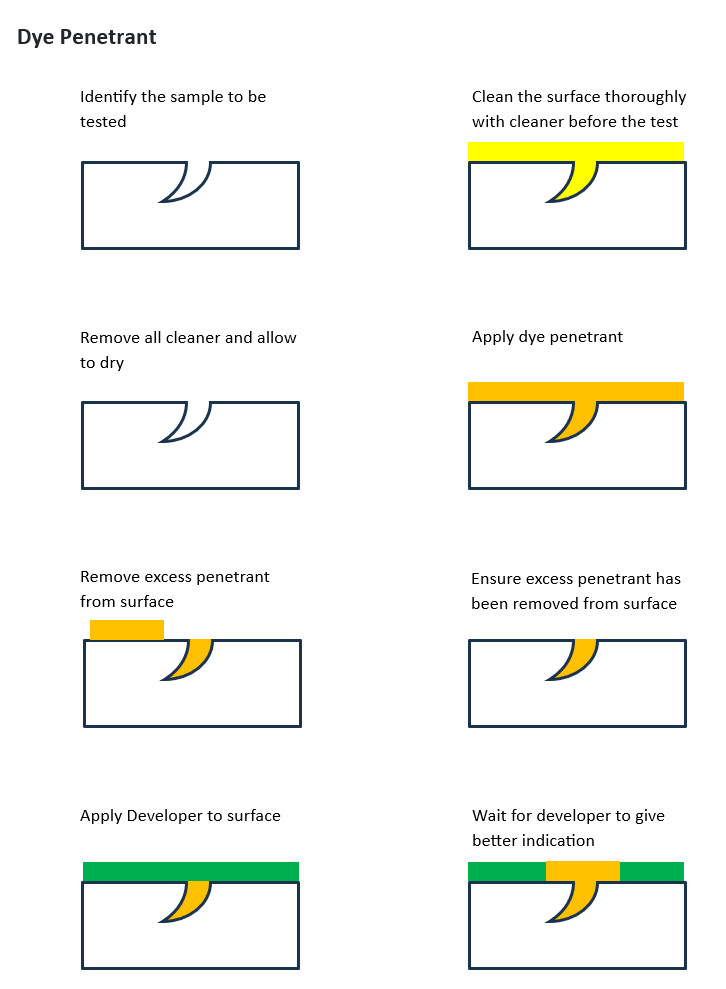

It needs a clean surface, so the surfaces must be cleaned from dust, rust, or scale before applying this technique. In this technique, you will use any colour, fluorescence, or visible liquid on the examined part.

After removing the excess penetrant after a specific time, a developer solution is applied that works according to the principle of capillary action.

Under ultraviolet radiations (1,000 micro-watts per centimetre squared intensity), the fluorescent is examined where the flaws are now visible. After development, one should not wait too long as the developer may over bleed, leading to misguiding detection.

Submit a review/ Get in touch